New control solutions for scientific applications

In the refrigeration business, part of the market covers various different scientific applications, each with specific needs depending on the substances handled.

Quite often, the stored substances have a very high economic and even strategic value, and consequently the units that can ensure the best store conditions for scientific applications are always chosen after careful technical-economic assessments.

These refrigeration units are mainly used in hospitals, pharmacies and analysis laboratories. In hospitals and pharmacies, the units are used to store many different types of thermosensitive medicines and biological materials, which require careful and precise temperature control, avoiding excessive sudden variations and fluctuations that may affect their properties.

In analysis laboratories, on the other hand, refrigerators and freezers are used to store biological and non-biological samples, as well as reagents, for which the risk of contamination or explosion needs to be minimised when dealing with highly volatile elements. The regulations regarding refrigeration units used for scientific and/or medical applications often require monitoring of the minimum and maximum temperatures reached in the unit, so as to ensure that the substances have been kept within the allowed ranges established by the pharmaceutical companies, in the case of medicines, or by the specific medical-health regulations in each country.

The importance of reliable temperature monitoring

Scientific applications require units that can ensure the highest reliability in ensuring the substances are stored in accordance with the specified conditions. Consequently, it is essential to report all possible situations in which the temperature conditions exceed the set limits and thus guarantee complete traceability, as detailed in the white paper entitled “The importance of temperature in pharmaceutical storage and the challenges for the cold chain".

Most scientific/medical regulations, in fact, require the minimum and maximum temperatures reached inside the unit to be recorded and displayed at different intervals, usually on a daily basis.

The temperature recordings can be managed in two main ways: manual and automatic. In manual mode, the operator manually records the temperatures, authenticates them and makes them accessible for a certain period of time, while with automatic management the entire procedure is handled by an electronic device.

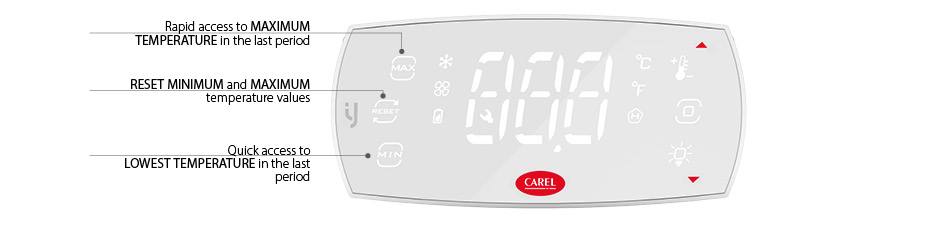

With a view to making interaction with the controller simpler and more intuitive for operators, CAREL controllers designed for scientific applications are equipped with a dedicated keypad for recalling the various saved temperatures and resetting them if necessary. At the same time, the Bluetooth antenna on some controllers allows interaction with a more familiar interface than the classic keypad, directly downloading temperature logs spanning up to five months.

The benefits of connectivity

One growing trend is clearly the progressive abandonment of manual operations in favour of new generation units with integrated connectivity. The main purpose is to reduce as much as possible the number of manual tasks that require know-how, responsibilities and direct costs for trained personnel, replacing these with automated routines and WiFi communication.

The reliability of the solution in terms of temperature recording and content preservation is mission critical. These needs have led to the adoption of connected solutions that allow the refrigerated units to communicate with each other, both in the same building via a local supervisory system, and remotely, allowing the manufacturer and/or maintenance technician to manage the individual units via a remote connection.

Reliability in all conditions

All the above considerations must also hold true in a blackout, i.e. when there is no mains power. It is therefore important to provide technical solutions that can keep temperature recording active and ensure that the products are stored at all times in the compliant temperature ranges. To meet this need, the iJ family, including the latest iJS for scientific applications, feature a battery backup port module option, capable of ensuring operation of the controller even during blackouts. This is done by managing an external battery and without needing additional devices for recharging. The system provides a direct connection to 6V batteries, and is compatible with a wide range of battery capacities to allow different periods of autonomous operation.

Main benefits

Fast and effective interaction

Fast and effective interaction

Ease of use through connectivity via app for temperature monitoring and the new dedicated keypad:

- Internal memory for temperature logging;

- Dedicated app for quick and easy data export;

- Interaction with iJS advanced in real time;

Built-in battery backup module

Built-in battery backup module

Highest reliability even in the event of a power failure, thanks to the built-in backup battery management module:

- Direct connection to the battery;

- No external charging system;

- Compatibility with a wide range of batteries.

Always-on connectivity

Maximum peace of mind in all conditions, with always-on connectivity to allow a prompt response and complete storage reports:

- Remote management of connected units via dedicated portal;

- Periodical reports with operating logs to ensure storage quality;

- Direct connection to supervisory systems and/or cloud via RS485 with standard Modbus protocol.

Ultra-low temperature ready

Management of two cascaded circuits, in which the first-stage evaporator is coupled to the second-stage condenser, meaning very low temperatures can be reached, even below -50°C, as required for the storage of certain vaccines:

- Logic for simultaneous control of two circuits in a cascade, activation priorities between stages and corresponding alarms;

- Compatibility with class B PT1000 temperature probes with accuracy in the ULT measurement ranges.

A complete range of control solutions for scientific applications

The CAREL offering of electronic control solutions for scientific applications ranges from the PJ easy family of entry-level products to the synergy between iJS and PGDX, combining the features of the latest addition to the iJ family, the iJS, with the versatility of a touch interface.

easy scientific

This boasts specific features and alarms, as well as a new keypad for managing the maximum and minimum temperatures recorded automatically by the controller.

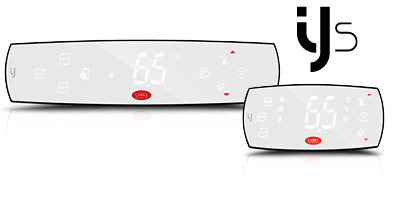

iJS for scientific applications

CAREL’s latest electronic controller for scientific refrigeration applications, iJS features the battery backup port module option, for managing external 6V batteries to ensure the controller remains operating at all times, even during blackouts. iJS also has special algorithms to respond to specific requirements in the field.

It is also possible to combine the top-of-the-range model iJS SPLIT with PGDX touch. The use of the iJS platform as the main board provides all the features of the standard product, while allowing customers to design their own graphic interface on the PGDX touch.